INSTACOAT 4G® is a ready-mixed powder that can be rapidly reconstituted in water, for the film coating of solid oral dosage forms. It contains polymer, plasticizer, pigments, etc. in optimal ratios to achieve significant benefits in terms of processability and product quality.

It is available in a wide range of shades to customer specifications.

| Features | Benefits |

|---|---|

| INSTACOAT System | |

|

|

|

|

|

|

|

|

|

|

| INSTACOAT 4G | |

|

|

|

|

|

|

|

|

|

|

|

|

All products are checked for the regulatory compliance of all ingredients in the target countries and market segments of sale. This determination is made at the time the initial formulation is established, based on customer-supplied information. If market countries and/or segments are extended once the formulation has been established, customers are encouraged to contact us to ensure that regulatory compliance is not compromised.

Purified water at up to 35% w/w solids

Variable-speed mechanical stirrer

Mixing Vessel

Determine the quantities of InstacoatTM 4G (35% w/w solids) and water required, based on the quantity of tablets to be coated and the target coating weight gain. e.g.: For coating 1.0 kg of tablets to 3% wt. gain, weigh 3 g Instacoat and 61.3 gm purified water at room temperature (includes 10% overage for losses).

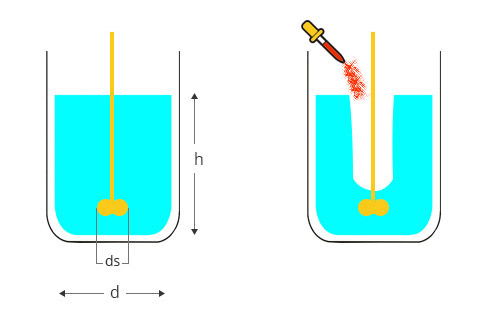

Add the weighed quantity of water to a mixing vessel.

Using a mechanical stirrer, stir the purified water to form a vortex.

Add required quantity of InstacoatTM 4G to the centre of the liquid vortex in a slow steady stream, avoiding clumping while maintaining a vortex. Once the entire quantity of Instacoat has been added, reduce the stirrer speed to eliminate the vortex. (Fig. 2) Continue mixing for 45 minutes.

| Side-vented (fully perforated) pans | Conventional (non perforated) pans | Continuous Coaters | |

|---|---|---|---|

| Pan diameter (inch) | 24-60 | 12 | 24-30 |

| Tablet load (kg) | 10-350 | 0.5-1.0 | 150-430 static |

| Tablet throughput (kg/hr) | N/A | N/A | 500-635 |

| Weight gain (%) | 2.5-3.0 | ||

| Number of guns | 1-6 | 1-2 | 14-22 |

| Liquid nozzle diameter (mm | 1.0-1.2 | ||

| Atomising air pressure (bar) | 3.0-4.0 | ||

| Pattern air pressure | Set to achieve maximum uniform bed coverage | ||

| Tablet bed temperature (⁰C)* | 42-46 | ||

| Inlet air temperature (⁰C) | Set to achieve required bed temperature & process time | ||

| Suspension spray rate (g/min) | Set to achieve required bed temperature | ||

| Exhaust air volume | To maintain slight negative pressure in pan | ||

| Pan speed | To achieve steady tablet flow through spray zone | ||

*Tablet bed temperature offers the most effective way of controlling the coating process. Where this measurement is unavailable, exhaust temperature may be substituted. However, the relationship between the two measurements is complex and depends on several factors such as pan load, pan depression, pan design and airflow rate. Indicated exhaust temperature may be above or below the true bed temperature. It is recommended that the relationship between the two measurements is calibrated.

PVA; Plasticiser; Titanium Dioxide; Edible Pigments, Anti-Tack & Adhesion Enhancing agents.