INSTACOATTM SFC is an HPMC and sucrose based, high productivity, aqueous sugar film coating system in dry powder form for reconstitution in water.

| Features | Benefits |

|---|---|

| INSTACOAT System | |

|

|

|

|

|

|

|

|

|

|

| INSTACOAT SFC | |

|

|

|

|

|

|

|

|

|

|

All products are checked for the regulatory compliance of all ingredients in the target countries and market segments of sale. This determination is made at the time the initial formulation is established, based on customer-supplied information. If market countries and/or segments are extended once the formulation has been established, customers are encouraged to contact us to ensure that regulatory compliance is not compromised.

INSTACOATTM SFC is an HPMC and sucrose based, high productivity, aqueous sugar film coating system in dry powder form for reconstitution in water. It offers replacement of inefficient conventional ladled processes with an atomized spray system capable of application in all types and sizes of coating equipment, with opportunities for automation. The attractive appearance and taste of conventional sugar-coating are retained.

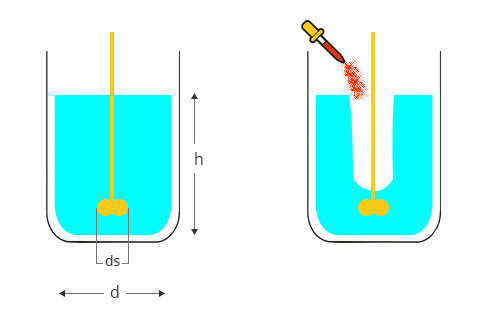

Instacoat SFC is applied in two stages using the same formulation but at different solids levels i) as a shaping base coat and ii) as a smoothing coat. Weight gain requirements at each stage can be varied according to the size and shape of the tablet and the degree of rounding and smoothing that is required. The two stages can be applied sequentially without process interruption.

The following guidance reflects a typical system.

Aqueous: Purified water at up to 26% w/w solids (Base coat)

Aqueous: Purified water at up to 14% w/w solids (Smoothing coat) Purified water at 80°C ±10°C is recommended. Maintenance of this temperature during coating is not necessary.

Variable-speed mechanical stirrer

Mixing Vessel

Base Coat:

Solids level = 26 %

Suggested weight gain = 40 to 60 %.

Determine the amount of Instacoat SFC (26% w/w solids) and water required, based on the batch size of product and the target coating weight. It is normal allow 10% overage to compensate for process losses.

For example: To coat 1.0 kg of tablets to a nominal 50 % wt. gain, weigh -

550 grams Instacoat SFC

1.565 kg hot purified water

Smoothing Coat:

Reconstitution Level = 14%

Weight gain = 2.0 to 6.0 %

Smoothing weight gain may affect shade of coloured coatings and can be adjusted to meet requirements.

Determine the amount of Instacoat SFC (14% w/w solids), and water required, based on the quantity of product to be coated and the target coating weight.

For Example: To coat 1.0 kg of tablets to a nominal 4 % wt. gain, Weigh

44 grams Instacoat SFC

270 grams purified water.

Place about 1.9 kg of purified water in a suitable vesse

Heat the purified water to 80°C + 10°C.

In the mixing vessel place 1.565 g of the hot water for the base coat

In another mixing vessel place 270 g of the hot water for the smoothing coat

In each case, stir the water to form a vortex using a propeller stirrer

Add the required quantities of Instacoat SFC to the centre of the liquid vortex in a slow steady stream, avoiding clumping and maintaining a vortex.

Continue mixing for 45 minutes.

Screen both dispersions 60 mesh or finer

| Side-vented (fully perforated) pans | Conventional (non perforated) pans | |

|---|---|---|

| Pan diameter (inch) | 12 | 12 |

| Tablet load (kg) | 0.8 to 1.2 | 0.8 to 1.2 |

| Weight gain (%) | 40-60 | |

| Number of guns | 1 | 1 |

| Liquid nozzle diameter (mm) | 1.0-1.2 | |

| Atomising air pressure (bar) | 0.5 to 1.5 | |

| Pattern air pressure | To achieve maximum uniform bed coverage | |

| Tablet bed temperature (⁰C) | 37-42 | |

| Inlet air temperature (⁰C) | Set to achieve required product bed temperature | |

| Suspension spray rate | Set to achieve required product bed temperature | |

| Exhaust air volume | To maintain slight negative pressure in pan | |

| Pan speed | Minimum for steady tablet flow through spray zone | |

*Tablet bed temperature offers the most effective way of controlling the coating process. Where this measurement is unavailable, exhaust temperature may be substituted. However, the relationship between the two measurements is complex and depends on several factors such as pan load, pan depression, pan design and airflow rate. Indicated exhaust temperature may be above or below the true bed temperature. It is recommended that the relationship between the two measurements is calibrated.

HPMC; Sucrose; Titanium Dioxide; Edible Pigments; Glidant.