Pharma Acrylic Co-polymers comprise Ideal Cures innovative brand of specialty products providing delayed release/enteric film coatings to drug-substance tablets requiring protection from the acidic environment in the stomach. These coatings also provide protection to the gastric mucosa from any local concentrations of any drug substances that could cause gastric irritation.

The Acrylic Co-polymers grades are available to take care of the enteric coating requirements in the entire gastro-intestinal tract and may also provide a means of colonic delivery with site specific drugs.

The range of Acrylic Co-polymers provides the capability for use with aqueous, organic or hydro-alcoholic solvents thus providing the versatility needed for use with all types of film coating equipment and processes. Applications include tablets, capsules, powders, pellets for Pharmaceutical, Herbal and Nutraceutical formulations.

The most widely used acrylic co-polymers for enteric film coating are based on Methacrylic Acid, Ethyl Acrylate and Methyl Methacrylates. Ideal Cures offers

Methacrylic Acid and Ethyl Acrylate Copolymer (1:1 as 30% aqueous dispersion) – ECOPOL L 30 D 55

Methacrylic Acid and Ethyl Acrylate Copolymer (1:1 dry powder) – ECOPOL L 100 55

Methacrylic Acid and Methylmethacrylate Copolymer (1:1 dry powder) – ECOPOL L 100

Methacrylic Acid and Methylmethacrylate Copolymer (1:2 dry powder) – ECOPOL S 100

Use the recommended reconstitution solvent system and follow the guidelines stated.

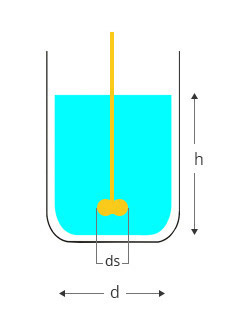

Stainless steel vessel with a capacity that is 25% higher than the total dispersion volume.

The height of the vessel should be nearly 25% more than its diameter.

The speed of the propeller stirrer should be variable and its blade diameter should be nearly 1/3rd of the vessel diameter. (As shown in Figure, h > d and ds = (1/ 3)d)

Take recommended quantity of ECOPOLTM (L 30 D 55/ L 100 55/ L 100 or S 100) and add gradually into the selected solvents mixture and continue mixing with continuous stirring. Continue the stirring up to 45 mins till the clear solution is formed.

Take recommended quantity of Titanium Dioxide, colorants, talc & plasticizer (DBS or DEP or TEC) & Polysorbate 80/60 in part quantity of solvent mixture. Pass the dispersion through Colloidal mill/homogenizer and homogenize for 10 mins & filter the homogenized/colloidal dispersion through # 80 mesh.

Add the colloidal dispersion in to Step 1 & continue the stirring during the entire coating process.

The use of high speed stirrer or homogenizer is not recommended.

The prepared dispersion should not be passed through colloid mill.

The dispersion may need gentle stirring during the operation to prevent settling.

| Parameters | Auto coater | Conventional Pan | |||

|---|---|---|---|---|---|

| Pan diameter | 24” | 48” | 60” | 12” | 36” |

| Solvent | Hydro-alcoholic | Hydro-alcoholic | Hydro-alcoholic | Hydro-alcoholic | Hydro-alcoholic |

| Solids content (% w/w) | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 |

| Pan speed* (rpm) | 10-14 | 3-5 | 1.5-3 | 18-20 | 8-12 |

| Baffles | 4-6 | 6-8 | 6-10 | 3 | 4 |

| Tablet charge**(kg) | 10-15 | 100-130 | 250-300 | 0.5-1 | 40-50 |

| Tablet bed temperature (ºC) | 30 – 35 | 30 – 35 | 30 – 35 | 30 – 35 | 30 – 35 |

| Spray nozzle (mm) | 1 | 1.2-1.5 | 1.2-1.5 | 1 | 1.2 |

| Number of spray guns | 1 | 2-3 | 4-6 | 1 | 1 |

| Atomizing air pressure (bars) | 1.5-2.5 | 2-2.8 | 2-3.0 | 1.2-1.8 | 1.5-2.2 |

| Spray procedure | Continuous | Continuous | Continuous | Continuous | Continuous |

| Spray rate (g/min) | 20-25 | 120-140 | 200-250 | 4-8 | 50-60 |

| Inlet air temperature (ºC) | 40-50 | 40-50 | 40-50 | 40-50 | 40-50 |

| Weight gain (%) | 8 | 8 | 8 | 8 | 8 |

* Pan speed would depend upon the tablet shape, size, friability and the number of baffles, so as to effect proper mixing during the coating process.

** Tablet charge may vary depending upon the tablet shape and size.